F.D.P. Piles

The FDP pile (Full Displacement Pile), also known as a lateral displacement pile, is a variant of the C.F.A. pile. Unlike the latter, the drilling of the FDP pile occurs without the removal of soil. In other words, the drilling tool compresses the soil during the advancement, preventing its removal. This is why it is also referred to as a compacting pile.

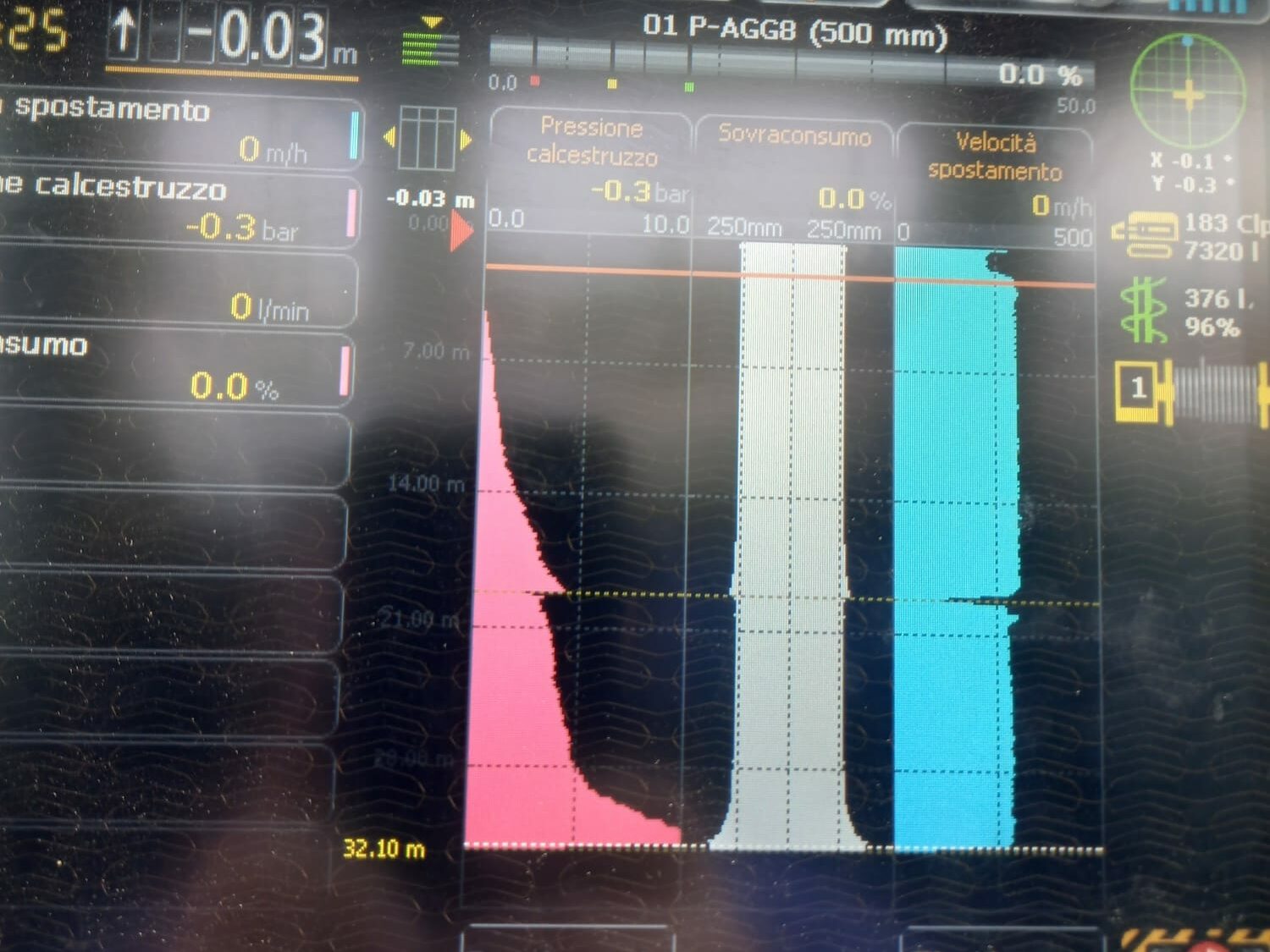

Once the desired depth is reached, the filling of the borehole with concrete is carried out similarly to C.F.A. piles, through the hollow core of the pushing rod, after the drilling is complete. The insertion of the reinforcement occurs after pouring, using the immersion method, similar to the procedure for C.F.A. piles.

The use of special SCC (self-compacting concrete) is absolutely necessary, with aggregates having a maximum diameter of 1.5 cm and additives that slightly delay the onset of the setting phase and prevent disintegration. This ensures the immersion insertion and the self-weight placement of the reinforcement cage.

Advantages / Disadvantages

- Cost savings due to the absence of soil removal

- Since there is no soil extraction, this pile can be executed even in reclamation environments

- The compaction effect results in a pile with higher load-bearing capacity

- Equipment with higher power is required

- Can only be used in compressible soils

- The maximum diameter of FDP piles is 800 mm, and the length is limited to 30 m

Need Consultation for Geotechnical Engineering Works?

Our technicians, engineers, and geologists will provide you with professional and accurate assistance.